Article By, Jake Wittenberg – Geospatial Sales Representative | Frontier Precision

As we move into a visual world of data collection with image sensors mounted to everything there seems to be a large misconception on what actually matters. Understanding the true importance of the image sensor size and type versus the number of megapixels a camera has is a topic that is not discussed often enough. A common misconception we have is thinking a high megapixel count is the true importance. This is not entirely true… Let’s dive in.

First there are two main types of image sensors used today in consumer grade cameras and professional use imaging tools: CCD and CMOS.

- CCD sensors are expensive to build but offer some of the best image capture capabilities. The sensor itself can create quite a bit of heat when in use. Because of this it can be difficult to manufacture a system around it cost effectively, such as in a point and shoot camera. However, these typically require less work to capture the same amount of light as a CMOS Sensor. This is due to the quality and way this image sensor captures light at a higher sensitivity. With that being said you can typically utilize a CCD sensor with a lower megapixel count and receive a better quality image than a CMOS Sensor that has more megapixels. Many high end professional cameras still use CCD sensors today. However, to give you a sense of scale, we’re talking $4000 for the cheapest entry level camera body (without a lens) to large megapixel medium format cameras in the $30K or more price range. This technology is also used in other professional applications such as in medical instruments and mobile imaging tools such as the Trimble MX7 and MX2. Size of the CCD image sensors can range largely depending upon use. Just remember, these have traditionally been much more sensitive at grabbing light than CMOS, but still deliver high quality low noise images.

- CMOS Sensors are relatively cheap to build and is why you see them being used in a wide array of imaging solutions today. Ranging from the latest smartphones to high end DSLR and Mirrorless camera systems. Most all consumer grade devices utilize sensors of this type due to the quality of images they can reproduce in respect to their low manufacturing cost. These sensors typically require more light than a CCD sensor to capture similar quality images. However, there is trade-off with the low cost. Most digital cameras utilizing CMOS sensors boast the ability to shoot with a high ISO*. They can require this extended range to capture images in low light conditions. Shooting with a higher ISO range doesn’t directly reflect better image quality. Again, this is a trade-off as higher ISO can lead to more noise in the image. Just as CCD sensors, CMOS sensors also come in all different sizes. These sizes have a major impact on image quality as well as crop factor of the image.

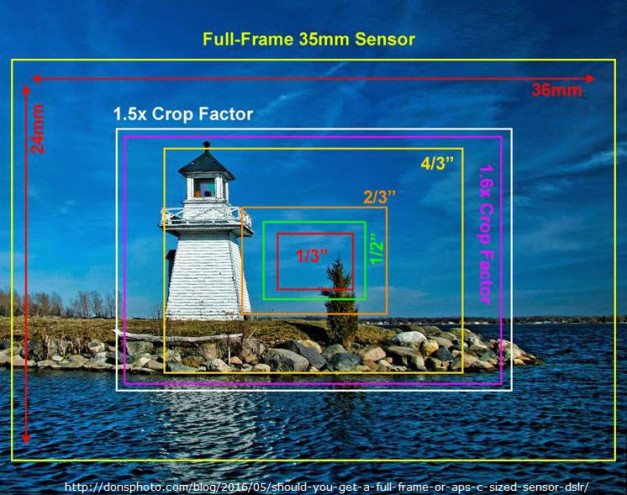

Let’s take a look:

Shot with the same focal length lens, the larger the image sensor in a camera, the larger the frame of the image. This plays a huge role in what is being captured by the image sensor. This is especially true when working with photogrammetry and are required to have overlap in photos. A larger sized sensor will require less photos. Below is a visual representation of what each image sensor can capture when utilizing the same focal length lens:

This also means the larger the image sensor the more capable the sensor is to take photos in low light conditions.

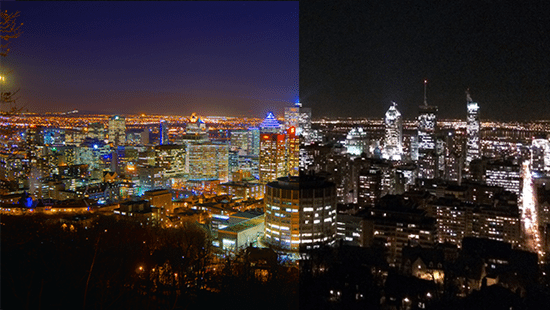

The image below on the left was captured with a DSLR and the right was captured with a smartphone. On the left you can see the available amount of light was much greater with the larger image sensor of the DSLR. The right you have no definition as the image sensor had a hard time capturing the light due to its smaller sensor size.

In addition to this the smaller image sensor will require a higher ISO setting to capture the same amount of light as a larger high sensitivity sensor. Even though the higher ISO range will capture more light, it will significantly degrade the image quality in low light conditions. The higher ISO creates noise in the image.

More information can be found on this information on TechRadar’s website HERE.

Image via Chris Mills at TechRadar

* ISO is a measurement of the image sensor sensitivity. The lower the ISO, the less sensitive the sensor, but the higher quality the image. There will be less noise in the image. The higher the ISO, the more sensitive the sensor. However, there will be more noise and less quality with the image.

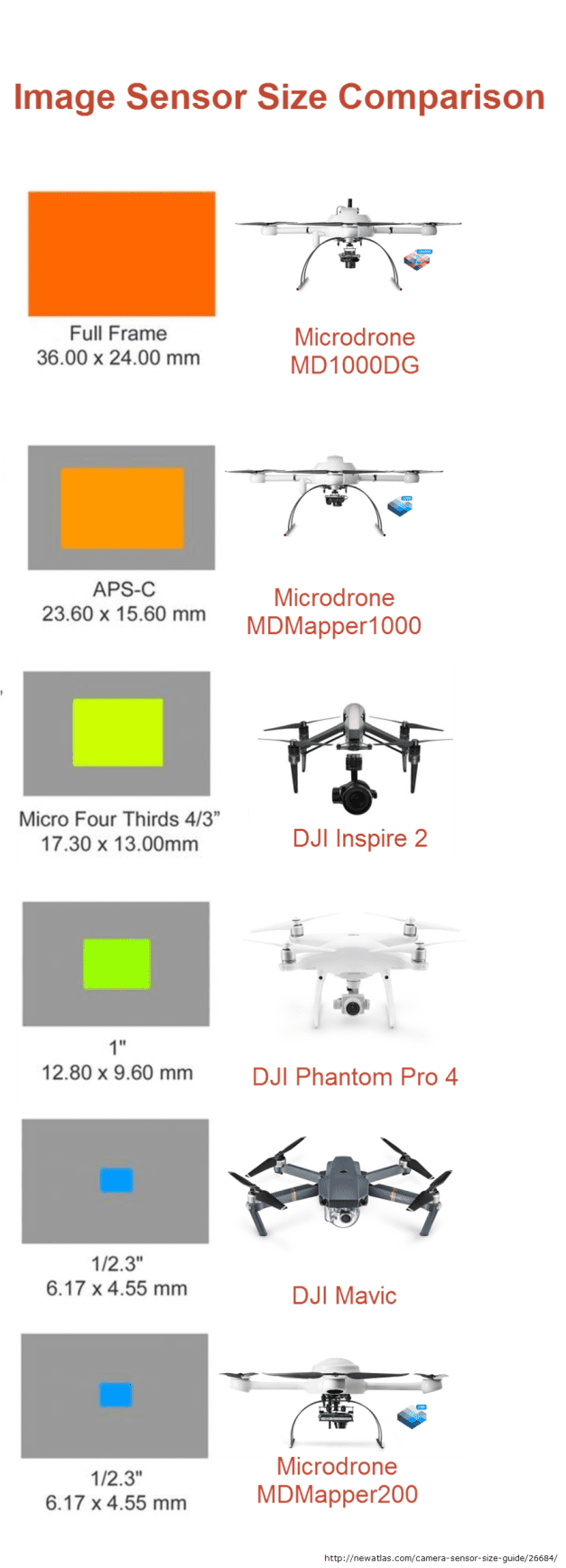

With that being said it’s important to put into perspective not just the type of sensor but the size as well. Our research shows that many drones on the market utilize a CMOS sensor. Here is a visual breakdown of what sensor size is being used by some of our more popular multi-rotor solutions:

When shopping around for fixed wing solutions you will see noticeable differences between options on the market. One popular comparison being the Trimble UX5HP and the SenseFly eBee. The UX5HP utilizes a Sony A7r mirrorless camera with a Full Frame sensor whereas the eBee utilizes a point and shoot camera with a 1/2.3″ type (7.76 mm) Exmor R® CMOS sensor. The full frame Sony A7r has the ability to capture more light in all conditions. The better image quality capture capabilities then result in a higher resolution photo that can produce more accurate photogrametric measurements.

Due to the larger image sensor size of the UX5 it can be flown at lower altitudes taking in more detail but capturing a larger area of view.

To recap, what you’re going to find in most scenarios is that the sensor size and sensor type play the most important role in image quality, not necessarily the available amount of megapixels. The larger sensor cameras are going to preform much better in overcast or low light situations. Low light situations still happen even in the middle of a sunny day. This might mean under bridges, building facades or canopy of trees.

We hope this helps put a visual on the effect image sensor type and size can play in image quality. Please feel free to contact Frontier Precision and we can assist you in finding the right solution for your project needs.

Products

Technical Services

If you require customized technical services and training, please contact Frontier Precision at 800-359-3703 or reach out to a local Frontier Precision location.

Training and Events

Frontier Precision offers affordable regularly scheduled certified training classes, online eLearning, webinars, as well as custom training options to meet your specific training needs.

About Frontier Precision

Contact Frontier Precision